For real this time, I swear.

Anyway, since I've yet to see a particularly satisfying DCC/sound installation procedure for a P2K FA2, I decided to write one up myself. Aside from just doing the install, I wanted to keep both the removable weight (to preserve the pulling power of this little Alco) and the moving fan (which is silly, but distinctive). Keeping those features doesn't leave that much space to work with, but thankfully the shell is roomy enough that, with some modern components, we can scrounge up just enough.

The parts you'll need for this installation are:

- NixTrainz Decoder Buddy Mini. Do save yourself some trouble and get the one with 1K ohm resistors built in. Don't get the full-size Decoder Buddy, because that won't fit. You could try a different motherboard if you like, but this one fits and isn't too expensive.

- 21-pin sound decoder of your choice. I'm using an ESU LokSound 5 decoder with sound file S0501 loaded, but if you prefer a different brand that's up to you. Just make sure that the sounds are appropriate to the Alco 244 prime mover.

- A speaker and baffle which can fit in the rear of the loco. I'm using RailMaster Hobbies' 20mm square "high-bass" speaker (P/N DHB20-8 and enclosure DS20E). I bought it as an experiment, and while I'm not convinced that it's bass-ier than other brands, it's no worse either. You could go a bit bigger than 20x20 mm, but keep in mind that the vents in the rear of the loco will restrict the width of what can fit there.

- A white LED for the headlight. It's an LED, just get one wherever.

- Double-sided foam tape, for securing stuff. You could probably get away with hot glue if you really wanted though.

|

| The bits you'll need. |

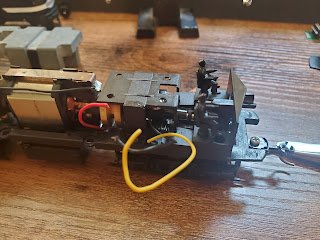

First, take the shell off and remove the weight. Do any servicing that the loco needs, and install couplers of your choice. You should have something that looks like this:

Now, we need to start disconnecting things. The headlight is easily removed by sliding off the clear wire covers, then gently pulling the wires apart. Once it's off, use nippers to break the four melted circle connections on the cover, and/or just pry it off with a flat-headed screwdriver.

Beneath the cover sits a bundle of diodes, which will not be necessary with DCC. Cut or de-solder the wires as close as you can to the diodes, and discard the latter. Hang on to the extra bits of wire if you feel like re-using them.

Using a pair of nippers/sprue cutters, remove the four cylindrical posts, and cut the diode tabs and the back wall of the cab flush with the driveshaft cover. When it's done, it should look about like this:

Using the double-sided foam tape, attach the motherboard to the flat surface that you just created, being careful to leave a gap between the motherboard/decoder and the weight. The front/headlight end of the motherboard should face towards the front/cab end of the loco. The motherboard will extend slightly into the cab space between the figures, but this isn't too offensive once the shell is re-attached.

|

| Check to make sure that the weight and decoder don't interfere. |

|

| Cozy fit between the crew's shoulders |

At this point, it's easiest to remove the crew figures. Pull straight up and they should come free easily. This is also a good opportunity to give them a little bit of paint to make them stand out in the finished model.

If you put the decoder and weight on to check their fit, remove them and set them aside. Tin the soldering pads on the motherboard which are used in this installation: Front V+, A0F (headlight F0 front), T right (both), T left (front only), M1/2 (motor) and both SP (speaker). While your soldering iron is out, also remove any wires running to the upper motor contact.

|

| Motherboard with the necessary pads tinned |

With the decoder occupying the front of the body, the speaker will mount in the rear. Put a piece of double-sided tape on the rear frame, behind the fan assembly, being careful to leave the rear truck sufficient clearance.

Once the speaker and baffle are assembled they'll go on this tape, with the speaker facing forward. Ideally, the speaker wires should be routed to run up along the right/engineer's side of the loco. Oh, and this speaker mounting will block access to the rear coupler mounting screw, so if you haven't already installed the couplers that you want, hurry up and do that now. Then stick the speaker and housing in place.

With that done, it's time to wire everything up to the motherboard. Solder the wires as follows:

- Rear truck to the rear T right pad. Since the rear truck wire runs up the right side of the locomotive anyway, it's easiest to keep it there.

- Front truck to front T right pad. This needs to be on the same side (left or right) as the rear truck.

- Chassis (yellow or blue wire) to front T left pad. The "other" rail pickup is carried up from the trucks through the chassis, so this one needs to be on the opposite side as the individual truck wires.

- Upper motor contact to M2, and lower motor contact to M1. So far this has been correct for all three of my FA's, but you should probably test this for yourself. Also note that you may need to extend the wire coming from the lower motor contact. Be careful not to let anything short!

- LED to U+ and F0f. If you're careful you can do this without any wires, by bending and cutting the leads to appropriately position the headlight.

- Speaker wires to each SP pad. Again, it's easiest to run these up the right side of the body.

When you're done, it should look like this:

At this point, you can test your installation to make sure that everything works. Pop the decoder onto the motherboard, and set the loco on the track. If anything doesn't work, go back and double-check your work.

Just for safety, I like to put a little bit of Kapton tape on top of the motherboard and the edge of the weight. It's probably not strictly necessary, but it reassures me that nothing should short the leads once everything is back together.

Finally, put the figures back in the cab, put the weight on the frame, then the body on top. And there you go!

No comments:

Post a Comment